55 manuelle Arbeitsgänge

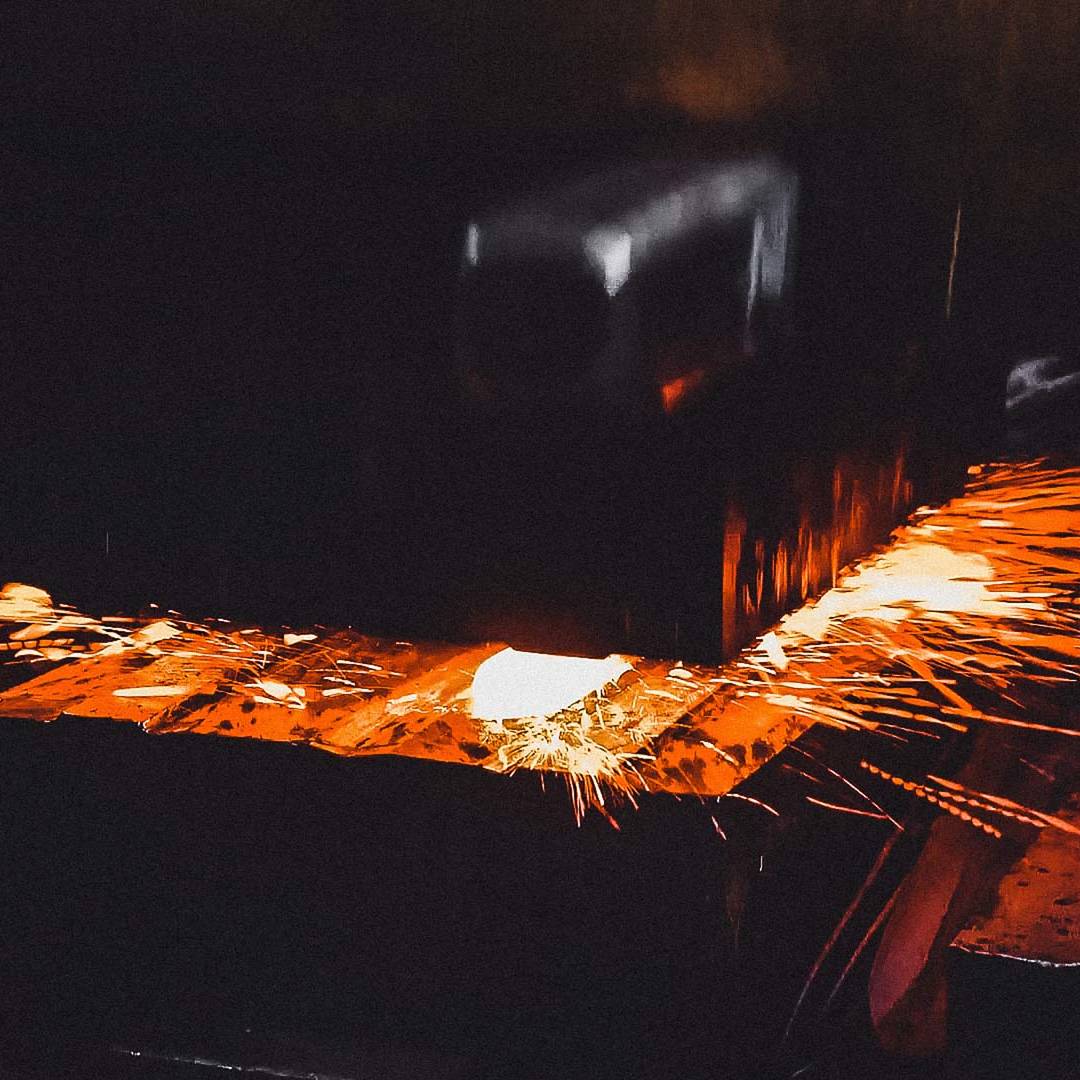

Alles beginnt in der Gesenkschmiede: Aus einem 8 Meter langen Stabstahl (Chrom-, Vanadium-, Molybdänmesserstahl) werden Spaltstücke abgeschnitten. Sie werden bis auf rund 1050 °C erhitzt und mit 3 bis 4 Hammerschlägen im Gesenk geschmiedet. Aus dem Schmiedestück wird schließlich der Messer-Rohling ausgestanzt.

Fertigungs-Schritte

Alles beginnt in der Gesenkschmiede: Aus einem 8 Meter langen Stabstahl (Chrom-, Vanadium-, Molybdänmesserstahl) werden Spaltstücke abgeschnitten. Sie werden bis auf rund 1050 °C erhitzt und mit 3 bis 4 Hammerschlägen im Gesenk geschmiedet. Aus dem Schmiedestück wird schließlich der Messer-Rohling ausgestanzt.

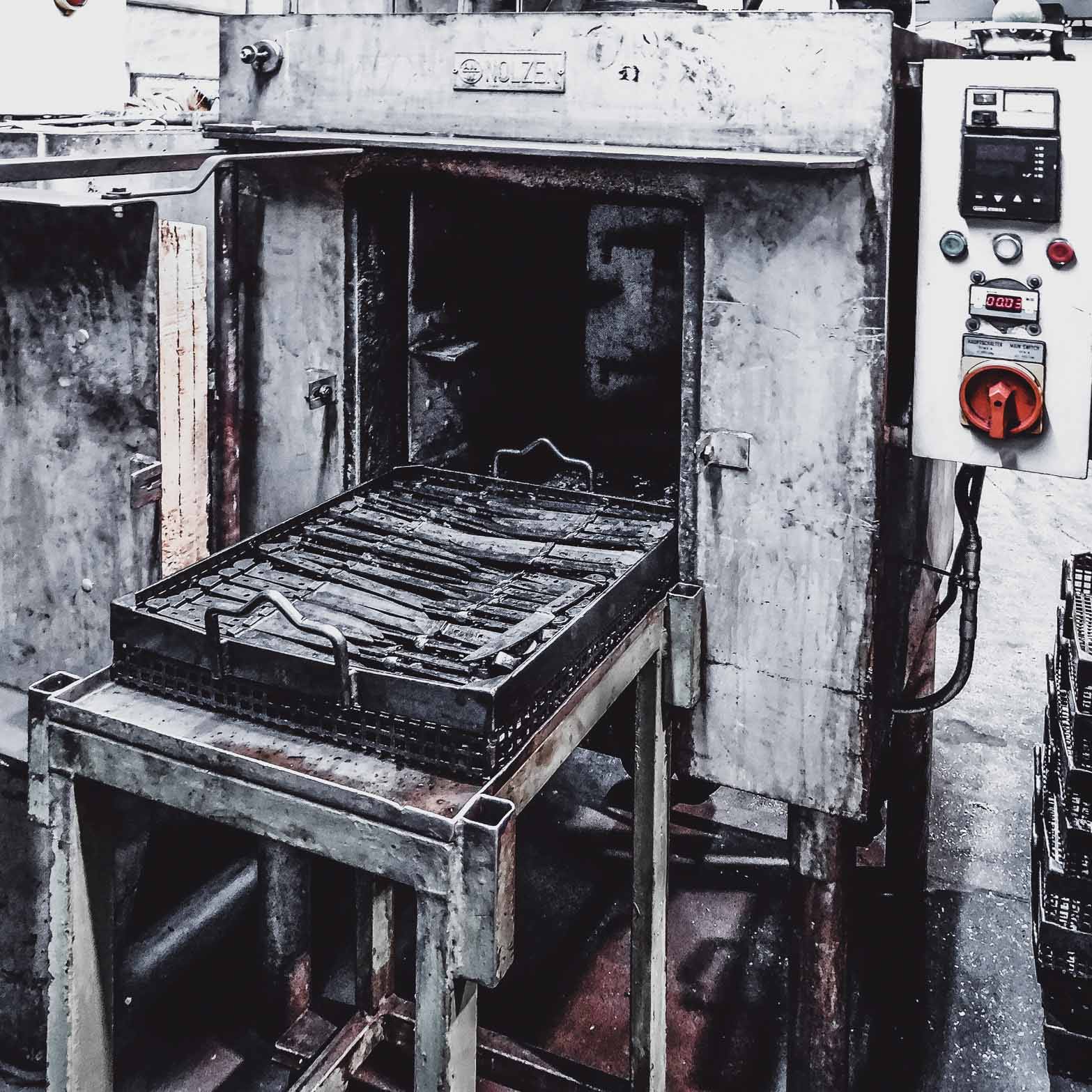

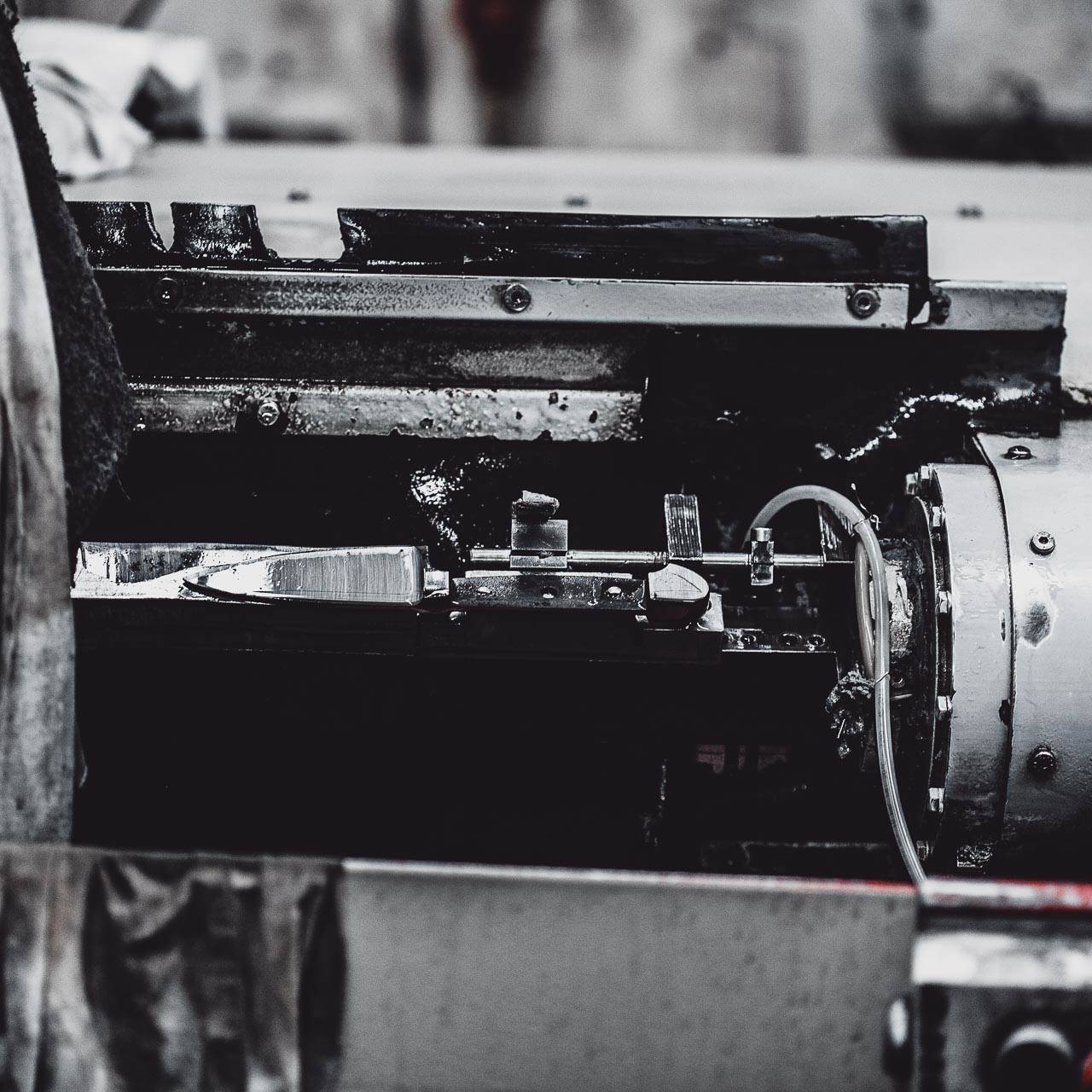

Zuerst wird das Klingenblatt vorgeschliffen, danach erfolgt das Vorschleifen des Messerrückens. Anschließend erfolgt der Feinschliff des Messerrückens und das Spitzschleifen des Kropfes. Die Innenseiten des Griffes werden vorgeschliffen. Das Vorschleifen der Kröpfe erfolgt in 5 Arbeitsschritten. Daraufhin folgt das Feinschleifen des Klingenblattes. Dies nennt sich auch „pliesten“. Bei Brotmessern wird nun der Wellenschliff angebracht und bei Kullenmessern die Kulle. Beim Tomaten-. Käse- und Steakmesser werden ebenfalls die Verzahnungen angebracht. Jetzt ist die Klinge fertiggeschliffen und der Griff kann montiert werden.

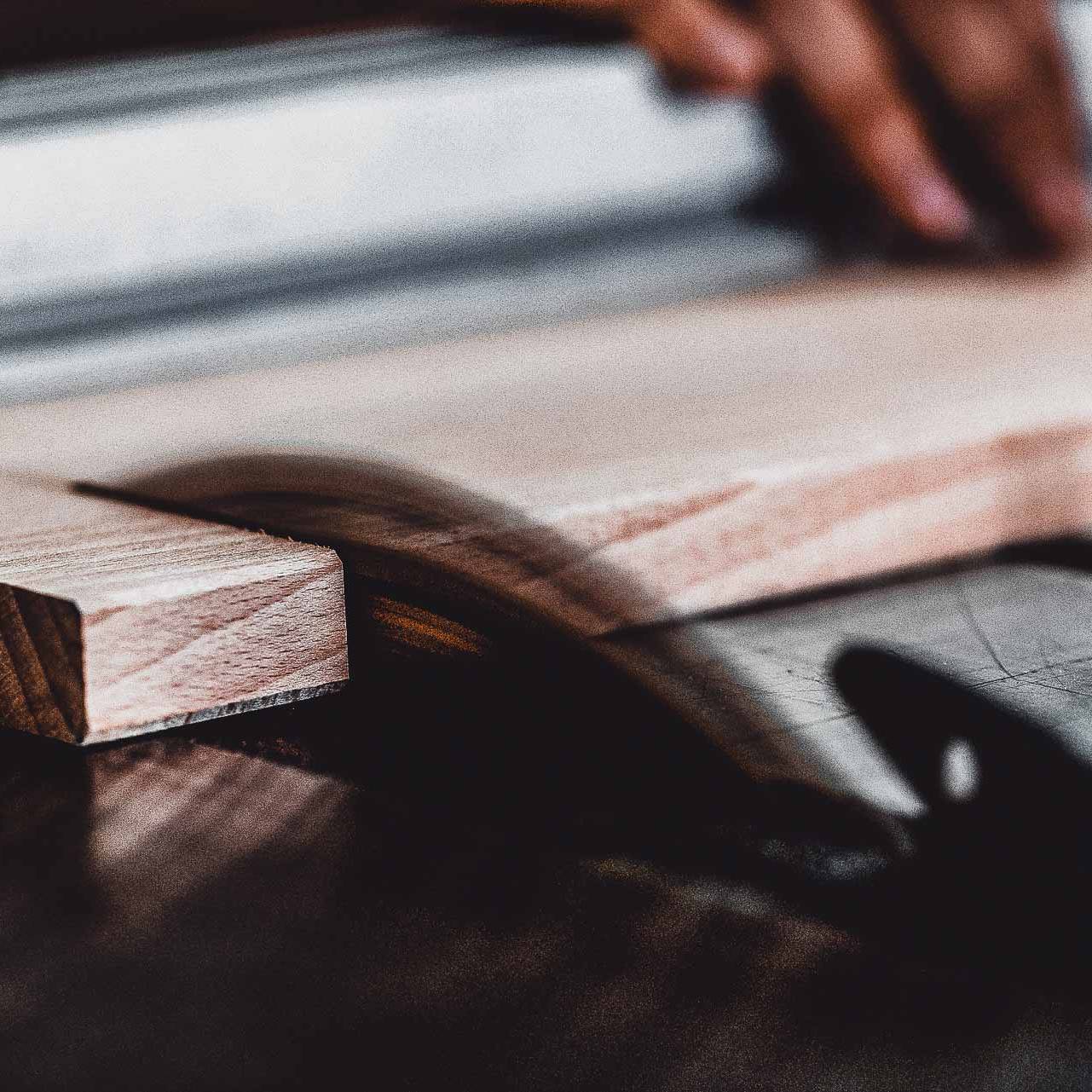

Aus dem Holz werden Kanteln geschnitten und konturgefräst. Die Kanteln werden nun an den Messergriff angepasst. Anschließend werden die Löcher für die Nieten gebohrt. Für die Nietköpfe muss in den Löchern eine Senkung vorgenommen werden. Griffstück und Klinge werden nun durch Nieten verbunden. Mit ca. fünf Arbeitsgängen wird das Holzstück grob an die Klinge beigeschliffen. Diese fünf Arbeitsgänge müssen mit einem feineren Schleifband wiederholt werden.

Jetzt bekommt der Messerrücken den Feinstschliff: Das Feinstschleifen des vorderen Kropfes erfolgt und die Messergriffe werden vorpoliert (gescheuert). Anschließend wird die mittlere Schmuckniete montiert und die Griffe werden feinpoliert. Daraufhin wird die Messerschneide geschliffen (abgezogen) und der Abzug poliert. Im nächsten Schritt wird das GÜDE Logo auf die Klinge geätzt.

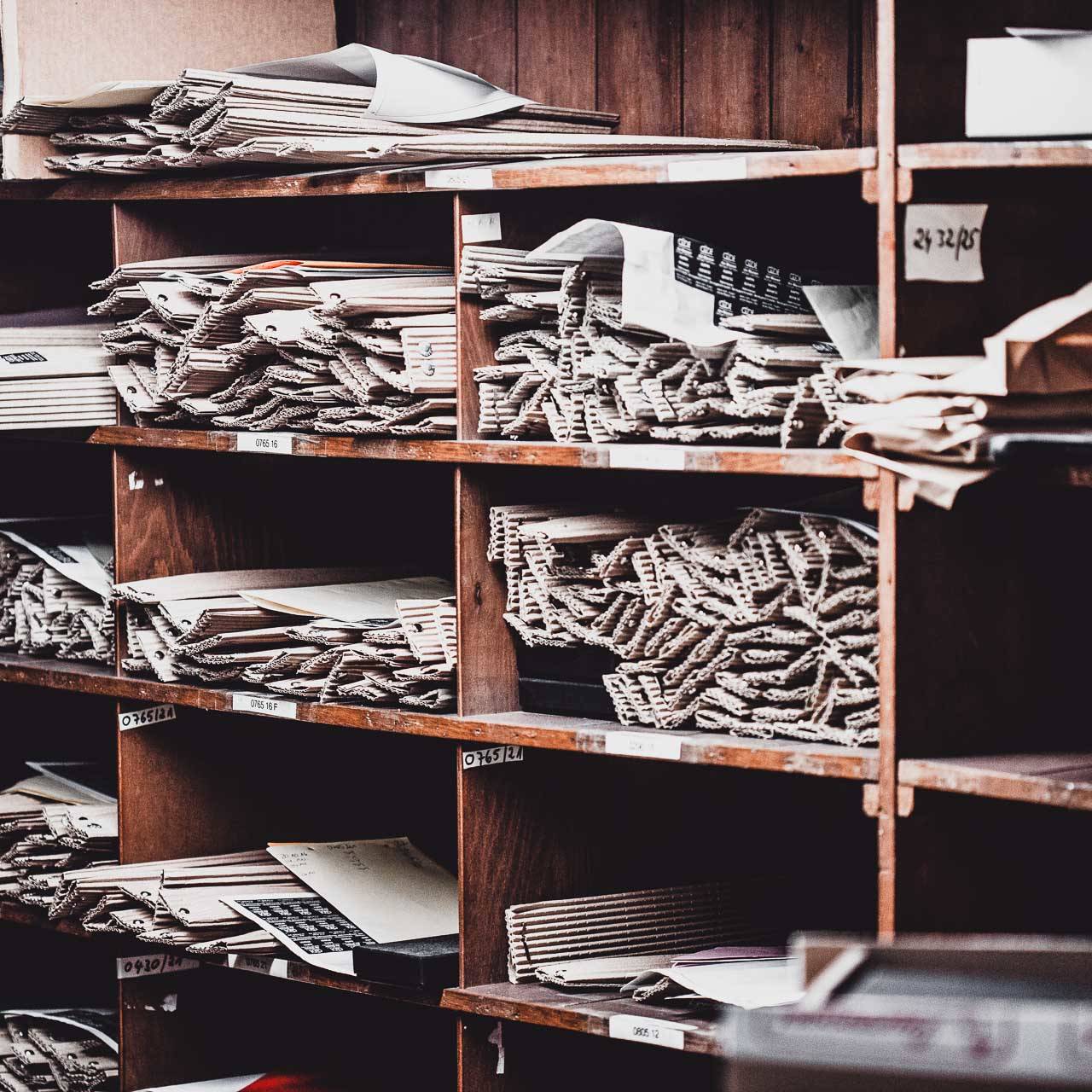

Anschließend werden die Messer gereinigt. Bevor die Messer versandfertig gemacht werden, erfolgt die Qualitätskontrolle. Nach der Qualitätskontrolle bekommen die Messer ihre Schutzhülle. Zum Schluss werden die handgefertigten Versandtaschen mit Nieten und entsprechenden Aufklebern versehen. Dann werden die fertigen Messer für den Versand bereitgelegt.